METAL STAMPING SERVICES

15 years metal stamping experience, CTS solution stamping provides high-quality precision stamping service, achieved ISO9001, ISO14001 certificates. CTS Solution produces metal stamped parts in quantities hundreds of thousands from our proprietary lifetime tooling. Our in-house tooling job shop is well known for high-quality dies from very simple shapes to the most complex.

To meet our basic quality requirement: meet customer needs and exceed customer expectations, CTS solution conducts regular staff training & equipment maintenance, established our complete quality management procedure. Keep improving quality management based on customer satisfaction surveys, strictly follow the quality procedures and strive to exceed customer expectations. CTS Solution staff understands the characteristics of each type of material allowing us to assist customers in finding the most economical material for their project. We are large enough of a stamping job shop to offer full-service capabilities, yet small enough to work with you day to day on a personal basis. One of our goals is to respond to requests for quotes within 24 hours.

Beyond the stamping, punching, forming, and deburring operations we also will provide secondary certified processes such as Heat Treating, Penetrate Inspect, Painting, and Plating. CTS Solution takes pride in our on-time delivery of high-quality parts. Simply put, when you choose the CTS solution, you do so with complete confidence. Contact us today to learn more about our metal stamping services.

COMPLETE RANGE OF METAL STAMPING SERVICES

Metal Stamping

|

Progressive Stamping Precision Metal Stamping Custom Metal Stamping Deep Drawn Stamping |

Metal Forming Metal Bending Reel To Reel Stamping Rivet Stamping |

Prototype Stamping Sheet Metal Stamping Micro Metal Stamping Terminals Stamping |

MATERIALS FOR METAL STAMPING PARTS

Stainless Steel Stamped Parts

Custom Stainless Steel Stamping Alloys (301, 304, 316, etc.)

Depending upon your unique project requirements, CTS Solution will help you select the best stainless-steel alloy for your needs. Common stainless steel stamping uses include aircraft engine manifolds, aircraft components, furnace fixtures, saw blades, bellows, welded tanks, chemical processing equipment, medical devices, and more. We stamp and tool the following SS types:

|

Types of Stainless Steel |

|

|

Stamping 301 Stainless Steel |

Moderately high tensile strength and corrosion resistance. Available in hard, half-hard and full hard. |

|

Stamping 304 Stainless Steel |

The workhorse of the 300 SS series, where moderate tensile properties, corrosion resistance are required, and most common in food-grade quality stainless steel & stainless-steel disc stamping |

|

Stamping 316 & 316L Stainless Steel |

Modification of the basic 300 SS series. Added molybdenum improves strength and corrosion resistance. Used for pharmaceutical, food processing, and marine environments. |

|

Stamping 321 & 347 Stainless Steel |

Variations of the basic 18-8 composition. Stabilized by alloy addition to improve weldability and high-temperature service. |

|

Stamping 17-7PH Stainless Steel |

Heat-treatable stainless steel with forming characteristics of 304. May be hardened up to 200 thousand tensile strengths after cold forming. |

Aluminum Stamped Parts

Stamping Aluminum Grades

Aluminum is a silvery-white metal that has comparable strength to carbon steel but at roughly one-third the density. This alloy is very ductile and malleable making it ideal for precision stamping processes.

Aluminum stamping can also be anodized to enhance surface hardness and corrosion resistance in challenging environments. Common aluminum stamping uses include:

|

Aluminum Alloy |

Common Applications |

|

Stamping 1100 Aluminum |

Spun parts, chemical equipment, and anodized parts |

|

Stamping 2024 Aluminum & 7075 Aluminum |

Aircraft & screw machine components |

|

Stamping 3003 Aluminum |

Hardware, furniture & cooking utensils |

|

Stamping 5052 Aluminum |

Sheet metal ductwork |

|

Stamping 6061 Aluminum |

Marine hardware, architectural structures & aerospace components |

|

Stamping 6063 Aluminum |

Extruded architectural structures & pipes |

Brass Stampings

Brass is an attractive, bright-gold alloy that is malleable, ductile, and possesses acoustic and antimicrobial qualities. Because of this, brass stampings are often found in musical instruments and medical equipment. Other common brass metal stamping uses include:

Ornamental hardware

Locks

Valves & gears

Bearings & fasteners

Plumbing & HVAC parts

Electrical applications

260 Brass Forging

C26000 Brass is the most commonly used for metal forging, as it is corrosion resistant and unlike steel and iron, it will not rust when exposed to the atmosphere. The varying levels of zinc and copper in 260 brass produce differences in conductivity, solder-ability, and hardness. Common applications of 260 brass include lamp fixtures, fasteners, fittings, and more. Before manufacturing your stamped brass components, our metal stamping experts recommend the type of alloy that best suits your application and budget. Then, we manufacture each brass part to the highest quality standards.

Brass Tooling Components

CTS Solution specializes in top-quality, close-tolerance metal components for clients around the country. Replacing conventional tooling and less-precise processes, our brass stamping operations include:

Blanking

Bending

Forming

Piercing

Coining

Committed to excellence at every project phase, CTS Solution is ISO 9001 certified for our proven quality management system. Our demonstrated commitment to consumer expectations and regulatory requirements helps our business partners optimize operational efficiency and guarantee product quality. Contact us today to learn more about our brass metal stamping services.

Copper Stampings

Copper and copper alloys are well suited for stamping applications because of their corrosion resistance, high ductility and cost-effective design. Often used for electrical and thermal applications, copper has an attractive patina finish that is appealing for consumer sectors, as well.

Copper Metal Stamping Characteristics

Features and advantages of copper include:

Conductivity & heat resistance: Second only to silver, copper possesses superior thermal conductivity that makes it a staple for electrical, HVAC and gas tubing applications.

Finish: A beautiful “colored” metal, copper is often selected for architectural, design hardware and consumer goods applications.

Durability & corrosion resistance: Copper is non-reactive, and does not become brittle in sunlight or cold temperatures. It can also be alloyed with other metals to improve corrosion resistance in adverse environmental conditions.

Malleability and ductility: Copper’s high ductility and malleability after hardening makes it ideal for wiring, tubing, and other industrial purposes.

Sanitary: Copper is a naturally hygienic metal with antimicrobial properties, making it useful for the food & beverage industry.

Sustainability: Copper is highly recyclable without degradation or quality loss, so it is an attractive green option.

Custom Copper Stampings

CTS Solution uses different types of copper for your stamping project. Our metal and alloy specialists can help you select the type of copper that is best for your application, and copper may be alloyed with other metals to improve strength and long-term durability. Common copper uses include:

Architectural features

Solar heat collectors

Air conditioning components

Electrical applications

Medical devices

Transformers, motors & cables

Plumbing & roofing

Hygienic vessels

Tooling Copper Components

Delivering superior quality, custom-crafted copper parts for a variety of industries, Pacific Metal Stampings tailors copper stamping and tooling to your unique application. We have developed a reputation for client-focused support and follow-through, and are dedicated to continual improvement through process innovation and training. Copper stamping operations include:

Blanking

Bending

Forming

Piercing

Coining

Schedule Copper Stamping & Tooling

An ISO 9001 certified industry leader, CTS Solution is proud to be a LEAN manufacturing award winner. Our team turns most quote requests around in 24 hours or less and works within your budget parameters to deliver cost-effective solutions for projects of all sizes. Contact us for information.

STAMPED METAL PARTS

Small metal parts

Deep drawing parts

Rivet parts

Contact pin

Contact clips

Spring clips

Shielding case

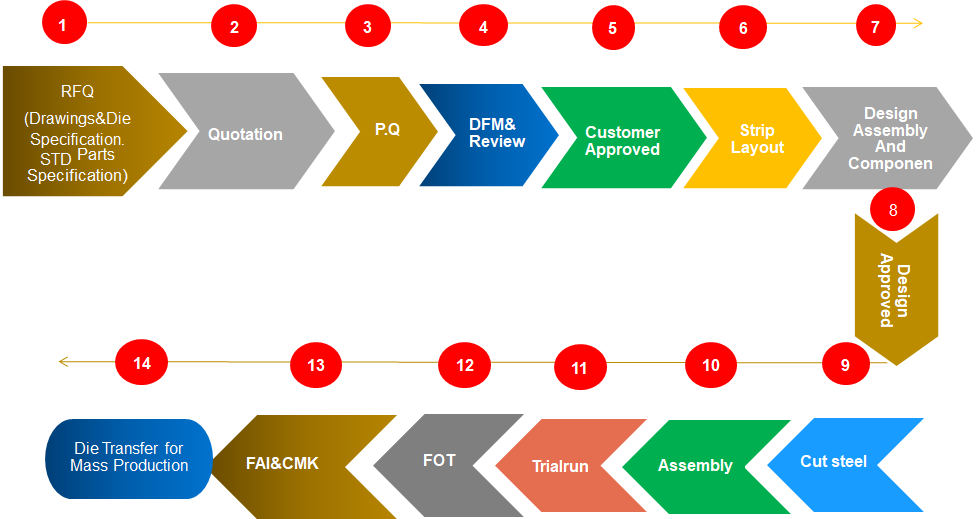

NEW PROJECT DEVELOPMENT PROCESS

MAKE CUSTOMER PRODUCT MORE COMPETITIVE

FIVE GOLDEN ROLES

On-time delivery.

All wise offering the best cost, compare the competition.

High-quality supply, NO agreements for failing.

Supply Chain, zero defect, means first time right!

Clear supply, Acc. Invoice, data, and transport information.

PRODUCT APPLICATION

Connector

Relay

Sensor

New energy battery

IC lead frame

Telecommunication

Solar photovoltaic

Medical electronic

Tact Switch

Automobile wire harness

INDUSTRY

Automotive

Appliances

Communications

Renewable Energy

Consumer Electronics

Medical/Medical Devices

Aerospace

Military/Defense

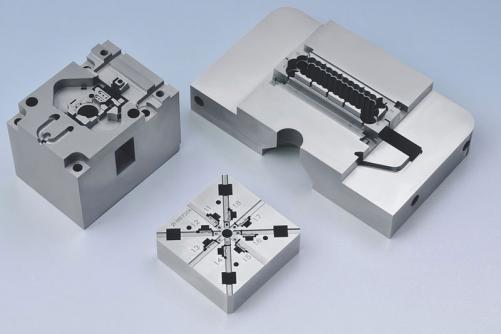

Punch And Die Set

Punch And Die Set

Punch Parts

Punch Parts